High pressure trunnion DBB ball valve introduction

High pressure trunnion DBB

ball valve is mainly suitable for the instrumentation but is also required as an alternative to the in-line installation of two valves.High pressure trunnion

DBB ball valve is possible to have the same result reducing costs, overall dimensions and the ability to bleed off the plant, by controlling a potential leakage of the plant.High pressure trunnion

DBB ball valve is recommended for any pressure class and ensure long-lasting seal.They can be supplied both in the Trunnion and in the Floating version.

High pressure trunnion DBB ball valve is the abbreviation for the double block and bleed ball valve.some of High pressure trunnion DBB ball valve has two balls and one or two needle valves,the two ball valves can opend and closed the medium and two needle valves can discharge pressure of the valves,the ball valve is designed to replace the complex form of the connection of multiple valves in traditional pipes,so as to reduce leakage points in the system and realize fast discharging and closing. High pressure trunnion DBB ball valve saves the installation procedures,reduces pressure in the pipe system,facilities instrument cleaning and maintenance and lowers the cost.

Using a single double block and bleed valve system versus 3 separate valves saves installation time, weight on the piping system, and space. It also cuts down the number of leak paths to the atmosphere, reducing the risk of hazards when transferring liquids dangerous to humans or the environment.

High pressure trunnion DBB ball valve specification

Body material: Carbon Steel, Stainless Steel, Alloy Steel.

Normal diameter: 1/2 - 24 Inch (DN15 - DN600).

End connection: Flanged X Flanged,Flanged X Threaded

Pressure range: 150 - 3000 LB/ 3000-15000 PSI.

Working temperature: -46℃ - +350℃.

Structure: (ball/needle/ball), Reduce Bore, One Piece Body.

Design: EEMUA 182, ASME B16.34.

Body Pattern: Three Piece.

Face to face: as per manufacturer's standard.

Test and inspection: EEMUA 182, API 598.

Operation: lever.

High pressure trunnion DBB ball valve feature

Wide range of materials of construction available

EEMUA 182, ASME B16.34 Design

Full Bore And Reduced Bore Design

Flanged, Welding, Hub, Threaded Ends

Anti Blow‐Out Stem

Anti Static Device

Fire Safe Design

High pressure trunnion DBB ball valve application

High pressure trunnion DBB ball valve is most commonly used in the oil and gas industry, but can also be helpful in many other industries.

It's typically used where bleeding the valve cavity is required, where piping needs isolation for maintenance, or for any of these other scenarios:

Prevent product contamination

Remove equipment from service for cleaning or repair

Meter calibration

Liquid service near waterways or municipalities

Transmission and storage

Chemical injection and sampling

Isolate instrumentation such as pressure indicators and lever gauges

Primary process steam

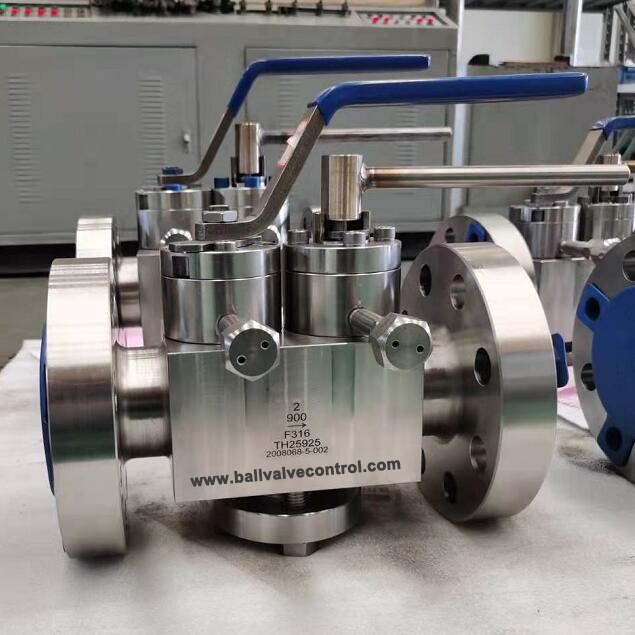

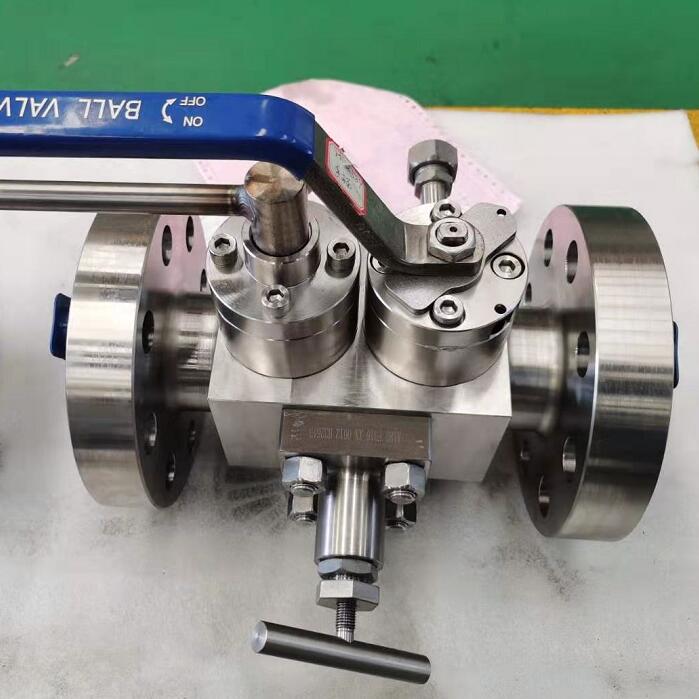

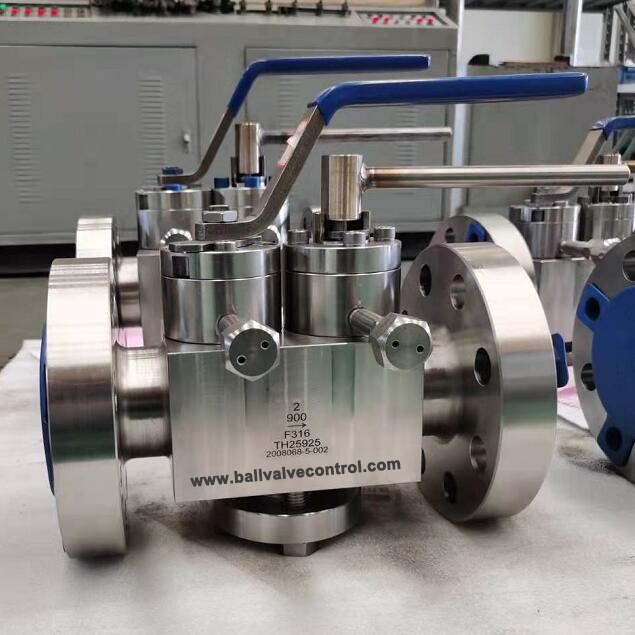

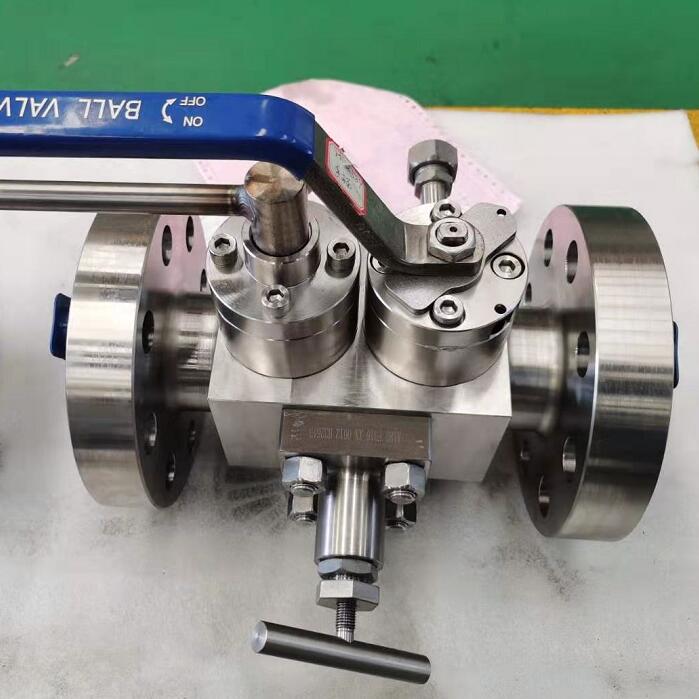

High pressure trunnion DBB ball valve product show

info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.com