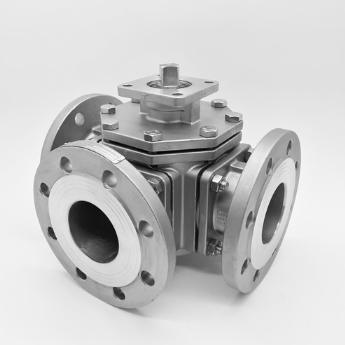

3 Way Ball Valve Manufacturer, Factory and Supplier, 3 Way Ball Valve has T port (Mixing type), L port (Diverting type) and Y type 120 degree and 135 degree structure. 3 way ball valve has 3 ports which is available in T-Port and L-Port Varieties depending on what flow pattern in required. 3 way valve is ideal if you are looking for a way to divert and control flow without the need for a Tee and multiple valves. These ball valves can be used as diverting function, where flow from one inlet can be diverted to either of the two outlets. They can also be used as input selector where the outlet is fed from either of the other two ports.L-Port valves can only direct the flow through 90 degrees or fully shut it off. T-Port valves can direct the flow in any way you want, but can't completely shut it off. To mix flows using a T-Port valve, the dynamic head of the two mixing streams should be consistent

3 Way Ball Valve Specification

Nominal pressure: PN1.6~42MPa、ANSI150LB~2500LB

Nominal diameter(mm) :DN15~DN400

Connection Type:

Flange、Thread、 Butt welding、 Socket welding

Body material: LCB、WCB、CF8、CF8M、CF3、CF3M

Valve seat form: Soft seat、metal seat (hardened sealing surface)

Proper temperature: Soft seat: -20~ + 200℃ Metal seat: -196~ + 400℃

Leakage level: ANSI VI

Design standards: GB/T12237、ASME B16.34

Face to face length: GB/T12221、ASME B16.10

Testing standards: GB/T13927、API598

Operation method: Manual、pneumatic、electric, etc.

Optional: Anti-static design、fire protection design、oil-free treatment、Copper

Prohibition、Spherical special treatment、Customers request painting

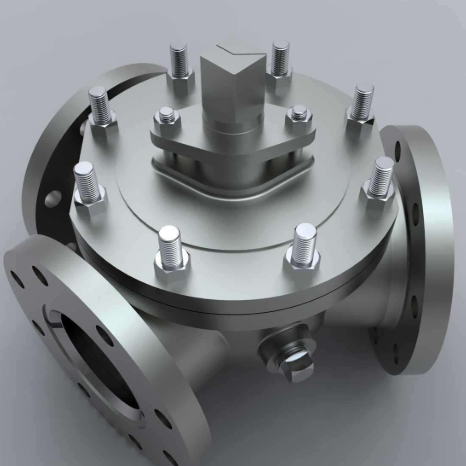

3 Way Ball Valve Material

1 Body: WCB、CF8、CF8M、CF3M etc.

2 Bonnet: WCB、CF8、CF8M、CF3M etc.

3 Ball: SS304、SS316、SS316L、SS316L + STL etc.

4 Seat: PTFE 、PPL、Metal seal, etc.

5 Cover board: WCB、CF8、CF8M、CF3M

6 Middle head gasket: PTFE、PPL、Metal gasket

7 Stem: 304、SS316、316L、17-4PH、S20910

8 Inverted seal: PTFE、PPL、Stainless steel wound graphite

9 O-ring: VITON

10 Filler: PTFE、PPL、Flexible graphite

11 Filling clamping ring: SS304

12 Butterfly spring: SS304

13 NUT: 2H、SS304

14 Gland of valve: CF8

15 Screw: B7、SS304

16 Screw: B7、SS304

Remark: Other material option can contact us.

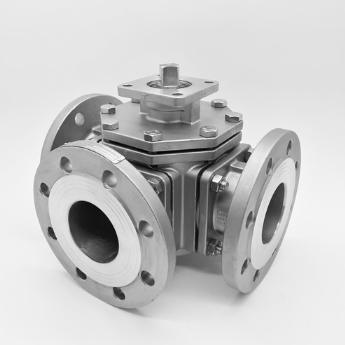

3 Way Ball Valve Flow direction

Three way ball valves have 3 ports. They are available in a variety of body materials and with all of the common end connections. They can be manually operated or automated with an electric or pneumatic actuator. They can be used as diverter valves, where flow a single inlet is diverted to either of the two other ports as the outlet. They can also be used as an input selector where a single outlet port is fed the flow from one of the other two ports as the supply inlet.

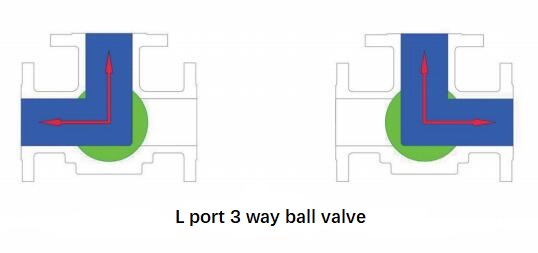

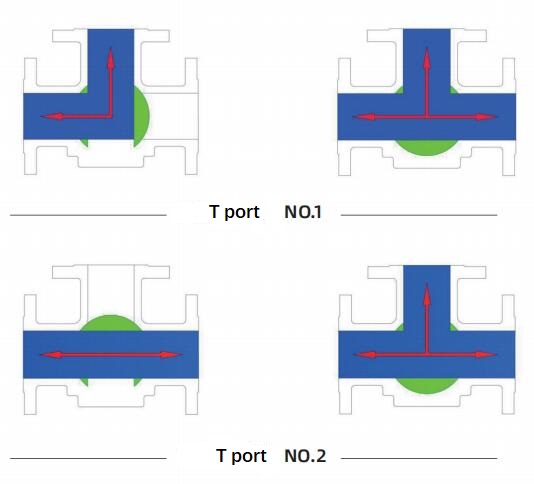

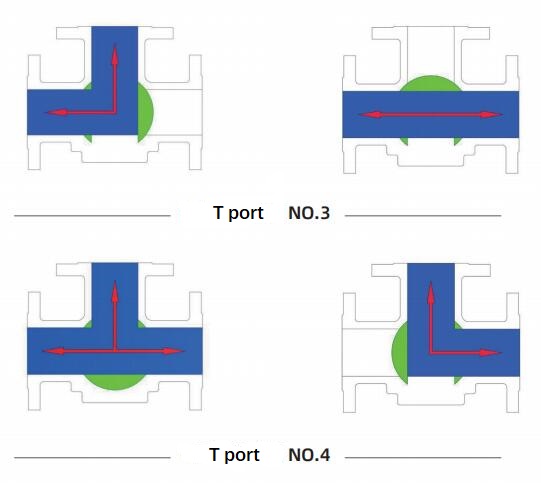

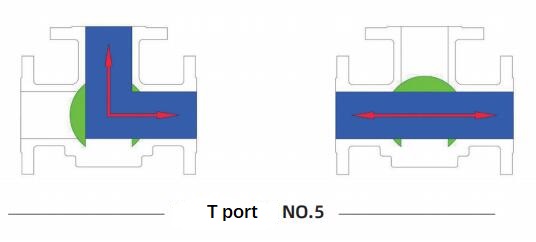

The bore through the ball (ball drilling) comes in two varieties, "L" port and "T" port 3 way ball valve flow direction as shown below:

How a 3 Way Ball Valve Works?

There are two types of 3 way ball valve: L-Port and T-Port. An L-Port 3 way ball valve can send flow one way or the other or can shut it off completely. A T-Port will perform all the same flow tasks as an L-Port 3 way ball valve but cannot be shut off. In addition, the T-Port can mix flows by sending or receiving flow to/from both ways of the Tee. The "T" and "L" refer to the shape of the opening in the ball.

3 way ball valve works by turning the handle, which rotates a ball in the valve body, to align the cut-out channels in the ball with the inlets and outlets of the valve. The "L" shape cut-out of the ball on an L-port valve sends fluid through 90 degrees from one port to another. The "T" shape cut-out of the ball on a T-port 3 way valve can also send from one port to another, but can also be rotated so that the T aligns with the "T" shape of the valve and all three ports are mixed.

3 way ball valve classification

According to the port design:

L port 3 way ball valve

Under certain operating conditions, L port 3 way ball valve is adopted to improve the flow switch, and L port 3 way ball valve is used to cut off three pipe, L port 3 way ball valve adopts three seat structure design, also can use four seat structure design, using large sphere design,The 3 way ball valve not only has the flow switching function of ordinary L port 3 way ball valve, but also has the function of sealing and cutting off the three-way at the same time.

T port 3 way ball valve

There is no difference between T port 3 way ball valve and L port 3 way ball valve appearance, but the structure of the valve body spool is different.The T port 3 way ball valve can make the three orthogonal pipelines connect with each other and block the third channel, playing the role of diversion and confluence.L port 3 way ball valve can only connect two orthogonal pipelines, and cannot maintain the interconnection of the third pipeline at the same time, and only plays the role of distribution.

T port ball valve can replace the L port ball valve.L port 3 way ball valve is used to switch the flow direction of the medium, which can connect the two channels perpendicular to each other.

T port 3 way ball valve can not only realize the switch of medium flow direction, but also make the three channels connected to each other, at the same time can also close any channel, make the other two channels connected, flexible control of the confluence or diversion of the pipeline intermediary.

Y type 3 way ball valve

Y type 3 way ball valve is 120 degree or 135 degree structure,which can be equipped with manual, worm wheel, pneumatic, electric, hydraulic drive control. Y type 3 way ball valve 120 degree Angle,135 degree Angle) divided into 120° and 135°body structure, Y type 3 way ball valve flow path is flat, small fluid resistance, strong flow capacity.When switching medium has no retention, it will not cause secondary pollution.Y type 3 way ball valve is widely used in powder conveying industry,which can be matched with electric actuators and pneumatic actuators for automatic control.

According to the actuator design:

Pneumatic 3 way ball valve

Pneumatic 3 way ball valve is made up of angle stroke piston pneumatic actuator and 3 way ball valve,which can be equipped with valve positioner to input control signal (4-20MADC or 1-5VDC) air source to control the operation.Pneumatic 3 way ball valve can also be equipped with travel limit switch, solenoid valve, pressure reducing valve and 0.4-0.7mpa air source to achieve switching operation, and send two pairs of passive contact signals indicating the switch of the valve. Pneumatic 3 way ball valve is suitable for switching medium flow direction and distributing or mixing medium in pipeline system of water supply, petrochemical, metallurgy, mining, light textile, energy, paper making, food and steel, etc.Pneumatic 3 way ball valve actuator parameter:Actuator type: GT, SR, ST, AT, AW series single - and double-acting pneumatic actuators.Air supply pressure: 0.4 ~ 0.7mpa.

Electric 3 way ball valve

Electric 3 way ball valve is composed of common on off or intelligent electric actuator and 3 way ball valve.which is widely used in gas, liquid, steam, oil and other corrosive media pipeline automation control.Power supply optional: AC220V, AV380V (other special),Protection level:IP67,Manual function:Electric actuator with manual valve opening and closing functions. Adjusting type:input 4~20mA signal, achieve the ball valve adjustment function.

info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.com